How Are Instant Noodles Made?

2019-07-15

Instant noodles is very popular all over the world. But do you know how are instant noodles made?

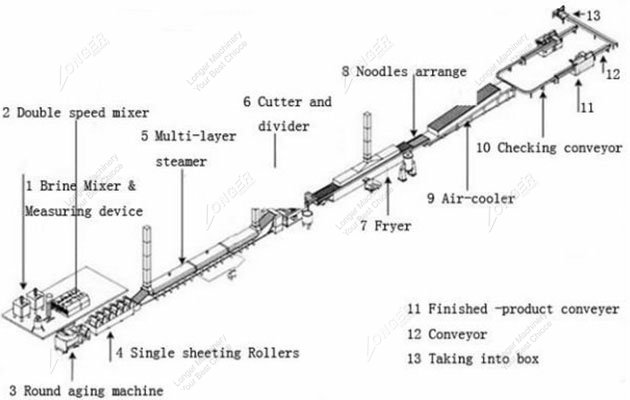

Main production process:

Flour mixing→aging→press→cutting→steaming→quantitative cutoff→frying→cooling→packing

Below we will explain in detail how are instant noodles made?

1. Flour mixing. It is to stir the flour and water evenly for a period of time to form a wet dough with certain processing properties. The flour is fully and uniformly absorbed, the particles are loose and the size is uniform.

2. Aging. This step is a process of further improving the processing properties of the dough by means of passage of time. The water is further infiltrated into the interior of the protein colloidal particles, fully absorbing water and expanding, and further forming a gluten network, which is actually a continuation of the dough process.

3. Press. The aged dough is pressed into two dough pieces by two parallel pressing rolls, and the two side pieces are overlapped in parallel, and are combined into a uniform thickness dough sheet.

4. Cutting. The belt is passed through a pair of knife rolls at high speed, cut into strips, and conveyed to the forming belt by a former. Due to the high speed of the cutter, the speed of the forming mesh belt is small, and the difference in speed between the two makes the noodle form a wave shape, which is a shape unique to the instant noodles.

5. Steaming. The noodles are steamed by steam at a specific temperature for a specific time. It is actually the process of gelatinization of starch. It is actually the process of gelatinization of starch. Gelatinization is the starch granules absorbing water at appropriate temperature to form a paste, and the starch molecules are arranged in a disorderly arrangement according to a certain regularity, so that the enzyme molecules can easily enter between the molecules and are easily digested and absorbed.

6. Frying. The instant noodles are placed in a frying box, and the water in the instant noodles is rapidly vaporized by the high temperature oil tank, and a porous structure is formed in the noodles, and the starch is further gelatinized.

7. The temperature of the cake just out of the fryer is too high, it will burn the packaging film and the soup, so the fan is usually cooled to room temperature for packaging.

8. Packing. This step is often done by a pillow type packing machine.

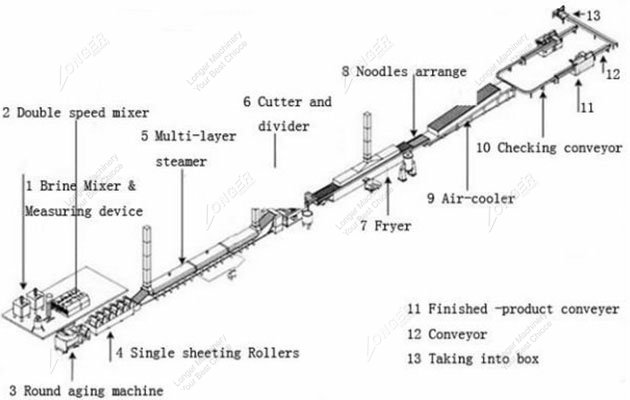

Main production process:

Flour mixing→aging→press→cutting→steaming→quantitative cutoff→frying→cooling→packing

Below we will explain in detail how are instant noodles made?

1. Flour mixing. It is to stir the flour and water evenly for a period of time to form a wet dough with certain processing properties. The flour is fully and uniformly absorbed, the particles are loose and the size is uniform.

2. Aging. This step is a process of further improving the processing properties of the dough by means of passage of time. The water is further infiltrated into the interior of the protein colloidal particles, fully absorbing water and expanding, and further forming a gluten network, which is actually a continuation of the dough process.

3. Press. The aged dough is pressed into two dough pieces by two parallel pressing rolls, and the two side pieces are overlapped in parallel, and are combined into a uniform thickness dough sheet.

4. Cutting. The belt is passed through a pair of knife rolls at high speed, cut into strips, and conveyed to the forming belt by a former. Due to the high speed of the cutter, the speed of the forming mesh belt is small, and the difference in speed between the two makes the noodle form a wave shape, which is a shape unique to the instant noodles.

5. Steaming. The noodles are steamed by steam at a specific temperature for a specific time. It is actually the process of gelatinization of starch. It is actually the process of gelatinization of starch. Gelatinization is the starch granules absorbing water at appropriate temperature to form a paste, and the starch molecules are arranged in a disorderly arrangement according to a certain regularity, so that the enzyme molecules can easily enter between the molecules and are easily digested and absorbed.

6. Frying. The instant noodles are placed in a frying box, and the water in the instant noodles is rapidly vaporized by the high temperature oil tank, and a porous structure is formed in the noodles, and the starch is further gelatinized.

7. The temperature of the cake just out of the fryer is too high, it will burn the packaging film and the soup, so the fan is usually cooled to room temperature for packaging.

8. Packing. This step is often done by a pillow type packing machine.

Message

Message