How to Fry Spring Roll Skins?

2019-11-26

Spring roll is a very popular snacks all over the world. And this is also the main way for eating spring roll skin. However, in some countries, spring roll skins are not made into spring rolls, but fried and eaten directly. This method makes the spring roll skin more crispy and tastes better. But how to fry spring roll skins?

It is very easy, you just need to heat the oil, then put the spring roll skin into the oil and take it out after about 10s (the actual time depends on the thickness of the spring roll skin)

Here we want to introduce you how to fry spring roll skins in factory.

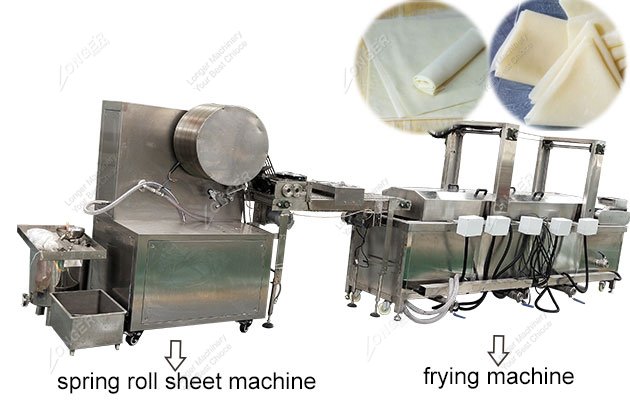

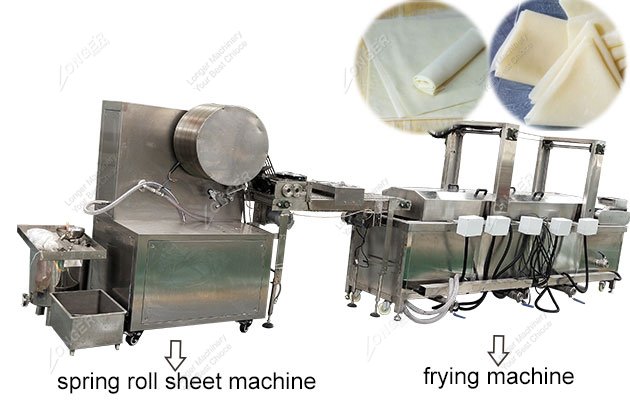

In order to meet the huge market demand, manufacturers usually connect the fryer directly after the spring roll skin machine. Spring roll skin making and frying are done automatically. The fryer plays an important role in the frying process.

Why use the machine to fry spring roll skins?

1. Mesh belt transmission adopts variable frequency stepless speed regulation, and the frying time can be controlled.

2. Equipped with an automatic lifting system, the upper cover and the mesh belt can be raised and lowered for easy cleaning.

3. A slag discharge system is installed at the bottom to discharge the generated residue at any time.

4. Adopting high-efficiency heat-conducting device, the energy utilization rate is high, which is beneficial to reducing the cost of the enterprise.

5. Use electricity or natural gas as heating energy, more clean and sanitary.

6. The upper and lower double-layer mesh belts are used for transmission, and the products are sandwiched between the double-layer mesh belts to prevent the products from floating.

7. Equipped with an oil circulation filtration system, which continuously filters the oil residue during the production process, reduces the acid value of the oil, reduces the color of the oil, and extends the service life of the edible oil by more than 10 times.

And about how to fry spring roll skins by the machine, we have detailed steps, welcome to contact us for free.

Email: sherry@machinehall.com

phone/whatsapp: +8615515573212

It is very easy, you just need to heat the oil, then put the spring roll skin into the oil and take it out after about 10s (the actual time depends on the thickness of the spring roll skin)

Here we want to introduce you how to fry spring roll skins in factory.

In order to meet the huge market demand, manufacturers usually connect the fryer directly after the spring roll skin machine. Spring roll skin making and frying are done automatically. The fryer plays an important role in the frying process.

Why use the machine to fry spring roll skins?

1. Mesh belt transmission adopts variable frequency stepless speed regulation, and the frying time can be controlled.

2. Equipped with an automatic lifting system, the upper cover and the mesh belt can be raised and lowered for easy cleaning.

3. A slag discharge system is installed at the bottom to discharge the generated residue at any time.

4. Adopting high-efficiency heat-conducting device, the energy utilization rate is high, which is beneficial to reducing the cost of the enterprise.

5. Use electricity or natural gas as heating energy, more clean and sanitary.

6. The upper and lower double-layer mesh belts are used for transmission, and the products are sandwiched between the double-layer mesh belts to prevent the products from floating.

7. Equipped with an oil circulation filtration system, which continuously filters the oil residue during the production process, reduces the acid value of the oil, reduces the color of the oil, and extends the service life of the edible oil by more than 10 times.

And about how to fry spring roll skins by the machine, we have detailed steps, welcome to contact us for free.

Email: sherry@machinehall.com

phone/whatsapp: +8615515573212

Message

Message