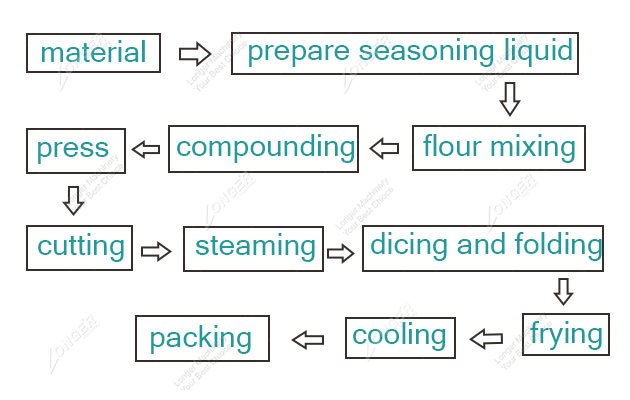

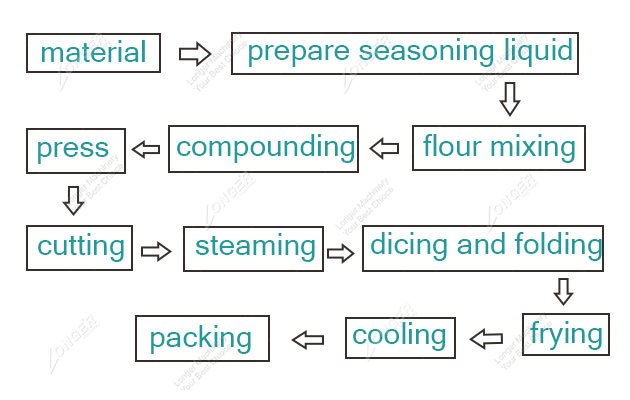

Instant Noodles Manufacturing Process

2019-07-09

Instant noodles as a kind of FMCG, is very popular, but do you know what is the instant noodles manufacturing process? Its production process mainly has 8 steps.

One. Raw materials entering the factory

1. In-plant inspection of flour and palm oil (for ingredients, water content, etc.)

2. Detection of raw materials required for the production of semi-finished products (soy sauce, chili powder, dehydrated vegetables, etc.)

Two. Mixing liquid and seasoning liquid

1. The mixed liquid is a solution obtained by adding a raw material such as salt or monosodium glutamate to a container of a constant volume of water.

2. Seasoning liquid: It is the solution that is poured onto the noodle before being fried.

Three. Mixing

1. Pour the flour into the sieve according to the direction of the distribution, and send it to the mixer by a screw conveyor.

2. The dry powder is stirred first, and then a certain amount of the mixed solution is added for regular wet powder stirring.

3. The flour is uniformly stirred and absorbed, and the protein in the flour is sufficiently absorbed to form a gluten network structure.

Four. Compounding, pressing, cutting

1. Compounding. This process is also called ripening, and the dough continuously forms a gluten network in the compound machine.

2. Pressing. The surface of the dough is calendered from thick to thin by the noodle machine to extend the gluten network structure, which is more elastic and highly malleable, and increases the taste of the instant noodles.

3. Cutting. When the dough sheet enters the cutter and is cut into noodles of the same width, the noodles of different widths can be produced by changing the cutter.

Five. Steaming

The steam is used to cook the noodles at a high temperature. The purpose of cooking is to make the starch gelatinized in a hydrated state (the fried instant noodles require a paste level > 85%).

Six. Quantitative dicing, folding spray

The quantitative dicing and folding device is one of the more complicated devices in the instant noodle production equipment.t sterilizes the steamed noodles according to the specified length, then folds the noodles into two layers and discharges them into the next process.

Seven. Frying

Deep-fried and dry is to put the is instant noodle into the frying box, cover the frying box with the lid of the instant noodle box, the dough piece is immersed in the high-temperature oil, the temperature rises, and the moisture present in the instant noodle vaporizes and escapes to achieve the purpose of dehydration. The frying temperature during frying is between 150 C and 170 C.

Eight. Cooling and packing

After frying, the temperature is generally about 100-120 degrees, and after cooling, the temperature of the noodle block is ≤ 40 degrees. Then packing.

The above is the instant noodles manufacturing process.

One. Raw materials entering the factory

1. In-plant inspection of flour and palm oil (for ingredients, water content, etc.)

2. Detection of raw materials required for the production of semi-finished products (soy sauce, chili powder, dehydrated vegetables, etc.)

Two. Mixing liquid and seasoning liquid

1. The mixed liquid is a solution obtained by adding a raw material such as salt or monosodium glutamate to a container of a constant volume of water.

2. Seasoning liquid: It is the solution that is poured onto the noodle before being fried.

Three. Mixing

1. Pour the flour into the sieve according to the direction of the distribution, and send it to the mixer by a screw conveyor.

2. The dry powder is stirred first, and then a certain amount of the mixed solution is added for regular wet powder stirring.

3. The flour is uniformly stirred and absorbed, and the protein in the flour is sufficiently absorbed to form a gluten network structure.

Four. Compounding, pressing, cutting

1. Compounding. This process is also called ripening, and the dough continuously forms a gluten network in the compound machine.

2. Pressing. The surface of the dough is calendered from thick to thin by the noodle machine to extend the gluten network structure, which is more elastic and highly malleable, and increases the taste of the instant noodles.

3. Cutting. When the dough sheet enters the cutter and is cut into noodles of the same width, the noodles of different widths can be produced by changing the cutter.

Five. Steaming

The steam is used to cook the noodles at a high temperature. The purpose of cooking is to make the starch gelatinized in a hydrated state (the fried instant noodles require a paste level > 85%).

Six. Quantitative dicing, folding spray

The quantitative dicing and folding device is one of the more complicated devices in the instant noodle production equipment.t sterilizes the steamed noodles according to the specified length, then folds the noodles into two layers and discharges them into the next process.

Seven. Frying

Deep-fried and dry is to put the is instant noodle into the frying box, cover the frying box with the lid of the instant noodle box, the dough piece is immersed in the high-temperature oil, the temperature rises, and the moisture present in the instant noodle vaporizes and escapes to achieve the purpose of dehydration. The frying temperature during frying is between 150 C and 170 C.

Eight. Cooling and packing

After frying, the temperature is generally about 100-120 degrees, and after cooling, the temperature of the noodle block is ≤ 40 degrees. Then packing.

The above is the instant noodles manufacturing process.

Message

Message