Sold Spring Roll Machine to Australia

2021-09-08

A spring roll machine with an output of about 6,000 pieces/h is sold to Australia. This Australia customer owns an old machine that can produce approximately 3,000 pieces per hour. Because of the increase in orders, the company needs to increase production. So they decided to replace a set of higher-volume equipment.

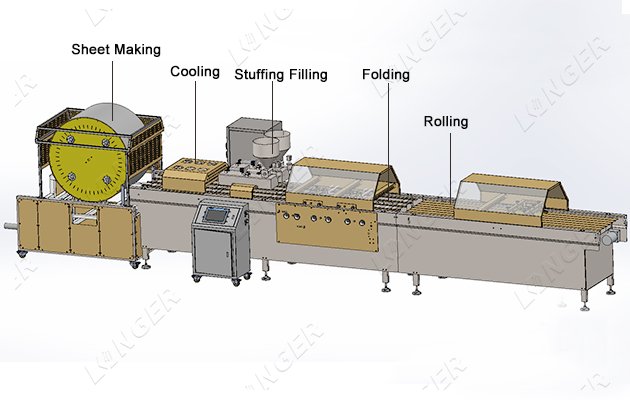

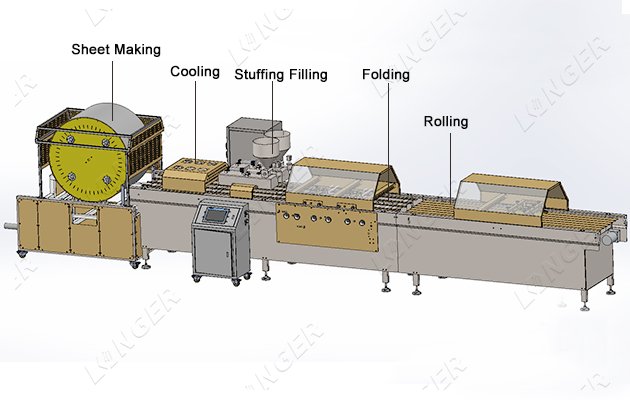

The spring roll line includes a sheet making machine, a conveyor, a cutting machine, a row, a stuffing filling and a folding mechanism connected in sequence. The sheet making machine includes a batter pump, a spray nozzle and a baking wheel. The batter pump is located at one end of the sheet making machine, and the batter pump is connected with the spray nozzle, which is installed at the bottom of the baking wheel. The baking wheel is connected to the conveyor, and the heating layer is evenly arranged in the wheel, and the heating layer is equipped with heat-conducting oil, which is connected with the thermocouple temperature controller. The conveyor is equipped with four traction rollers, one side of the traction roller is equipped with a lower roller, an upper roller is arranged above the lower roller, a horizontal shaft is arranged on one side of the lower roller, and a support frame is arranged on one side of the upper roller rod. Through temperature control, the quality of spring rolls can be guaranteed, and it has the advantages of simple structure, stable operation, high production efficiency, productivity saving, and reduced equipment loss.

Working flow:

After preparing the batter, pour it into the spring roll line hopper. After the machine is turned on, the batter is evenly spread on the baking wheel. After being quickly and evenly baked at 150-180 degrees Celsius, it is separated from the baking wheel. After cooling on the conveyor belt, the stuffing is placed, and the precisely designed wrapping mechanism enables the spring roll wrappers to fully wrap the stuffing, and the output can reach 6000 pieces per hour.

Features:

*Advanced design, hygienic and beautiful, safety devices, all parts in contact with food are made of food-grade stainless steel hygienic materials, and all electronic parts meet international safety standards, which are stable and safe.

*The production speed is fast, and the production speed and heating temperature can be adjusted according to actual production needs.

The spring roll line includes a sheet making machine, a conveyor, a cutting machine, a row, a stuffing filling and a folding mechanism connected in sequence. The sheet making machine includes a batter pump, a spray nozzle and a baking wheel. The batter pump is located at one end of the sheet making machine, and the batter pump is connected with the spray nozzle, which is installed at the bottom of the baking wheel. The baking wheel is connected to the conveyor, and the heating layer is evenly arranged in the wheel, and the heating layer is equipped with heat-conducting oil, which is connected with the thermocouple temperature controller. The conveyor is equipped with four traction rollers, one side of the traction roller is equipped with a lower roller, an upper roller is arranged above the lower roller, a horizontal shaft is arranged on one side of the lower roller, and a support frame is arranged on one side of the upper roller rod. Through temperature control, the quality of spring rolls can be guaranteed, and it has the advantages of simple structure, stable operation, high production efficiency, productivity saving, and reduced equipment loss.

Working flow:

After preparing the batter, pour it into the spring roll line hopper. After the machine is turned on, the batter is evenly spread on the baking wheel. After being quickly and evenly baked at 150-180 degrees Celsius, it is separated from the baking wheel. After cooling on the conveyor belt, the stuffing is placed, and the precisely designed wrapping mechanism enables the spring roll wrappers to fully wrap the stuffing, and the output can reach 6000 pieces per hour.

Features:

*Advanced design, hygienic and beautiful, safety devices, all parts in contact with food are made of food-grade stainless steel hygienic materials, and all electronic parts meet international safety standards, which are stable and safe.

*The production speed is fast, and the production speed and heating temperature can be adjusted according to actual production needs.

Message

Message