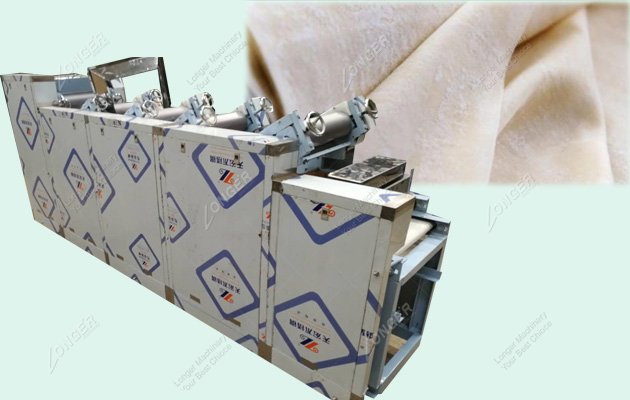

Commercial Dough Roller And Sheeter Machine Electric

Features

Features

The commercial dough roller machine is equipped with flour sheet transmission, automatic dusting, automatic folding of dough and clutch device.

Dough Sheeter Machine Working Principle:

The dough sheeter machine is composed of a driving mechanism, a pressing dough mechanism, a conveying mechanism, a dusting device and a rolling device. It rolls the dough from the active pressing roll and the passive pressing roll into a dough sheet and drops it on the conveyor belt while sprinkling the flour on the dough sheet.

The front part of the conveyor belt corresponds to a rolling device, and the bottom of the front end of the conveyor belt is connected with a scraping surface sliding plate. According to different rolling device, a dough sheet of different thickness can be produced.

Electric Dough Roller Machine Features:

〇 Good quality: high precision, the production of the dough sheet evenly, smooth, good taste.

〇 Using large diameter roller rolling, increase the pressure, calendering several times, processing and production of high-quality dough sheet.

〇 The electric dough roller machine is made of stainless steel, it can make a dough sheet with a thickness of 0.3---3mm.

〇 High efficiency: the width of the dough sheet is large, the finished product rate is high.

〇 Save time and effort, automatic dusting, folding automatically, time-saving and labor-saving effect is good.

〇 The power of the commercial dough roller machine is also very reasonable. It does not burn for more than ten hours in continuous operation, consumes less power, and has stable voltage. It can save a lot of electricity and reduce production cost every day.

Dough Sheeter Machine Working Principle:

The dough sheeter machine is composed of a driving mechanism, a pressing dough mechanism, a conveying mechanism, a dusting device and a rolling device. It rolls the dough from the active pressing roll and the passive pressing roll into a dough sheet and drops it on the conveyor belt while sprinkling the flour on the dough sheet.

The front part of the conveyor belt corresponds to a rolling device, and the bottom of the front end of the conveyor belt is connected with a scraping surface sliding plate. According to different rolling device, a dough sheet of different thickness can be produced.

Electric Dough Roller Machine Features:

〇 Good quality: high precision, the production of the dough sheet evenly, smooth, good taste.

〇 Using large diameter roller rolling, increase the pressure, calendering several times, processing and production of high-quality dough sheet.

〇 The electric dough roller machine is made of stainless steel, it can make a dough sheet with a thickness of 0.3---3mm.

〇 High efficiency: the width of the dough sheet is large, the finished product rate is high.

〇 Save time and effort, automatic dusting, folding automatically, time-saving and labor-saving effect is good.

〇 The power of the commercial dough roller machine is also very reasonable. It does not burn for more than ten hours in continuous operation, consumes less power, and has stable voltage. It can save a lot of electricity and reduce production cost every day.

Technical Data

Technical Data

| Model | LG-6-250 | LG-6-260 |

| Width of dough sheet | 250mm | 260mm |

| Size of king roller | 100*250mm | 140*260mm |

| Capacity | 200kg/h | 260 kg/h |

| Power | 3kw | 4kw |

| Weight | 700kg | 900kg |

| Dimension | 2600*650*1370mm | 3200*680*1370mm |

Related Products

Related Products